With our list of inspection equipment, A.J. Rose is able to control a wide range of unique specifications. Our equipment is maintained and certified on a regular basis to meet the most stringent quality standards.

Delivering a perfect product has been our goal since 1922. No matter how complex the job or how large the volume, we continuously supply parts that meet or exceed expectations. Our customers turn to us when precision and consistency are absolutely critical.

To provide an industry-leading quality process it must be comprehensive, making quality assurance a priority throughout every step of production. This reduces costly downtime and ensures a better result.

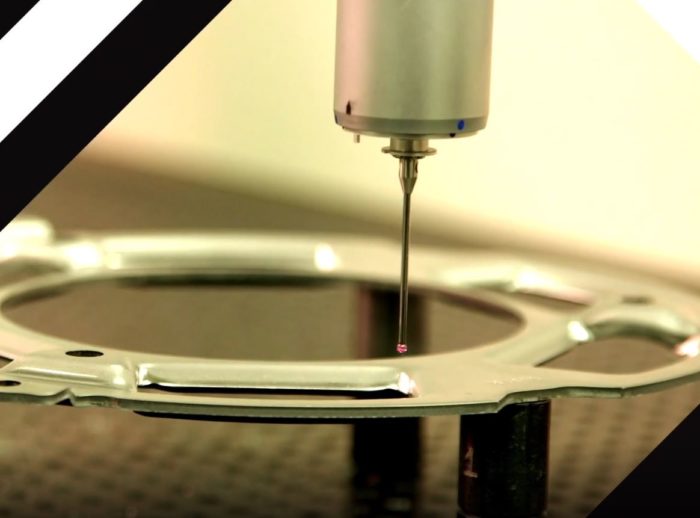

A.J. Rose is IATF 16949: 2016 certified and meets or exceeds all relevant quality standards. Quality assurance is built into each stage of our manufacturing, beginning at material receiving inspection. We utilize in-die sensing, in-process controls and many different inspection techniques. For many of our customers, we design and build 100% automated inspection cells to maximize accuracy and efficiency.

When you have zero tolerance for error, A.J. Rose is your perfect partner.

A.J. Rose offers 100% automated inspection to check all customer-critical features prior to packaging. We design and build each cell custom for the part being inspected, utilizing robotics and automation. Many of these cells both inspect and pack the parts, never handled by a person before arriving to our customer.

With our list of inspection equipment, A.J. Rose is able to control a wide range of unique specifications. Our equipment is maintained and certified on a regular basis to meet the most stringent quality standards.