At its heart, A.J. Rose Manufacturing Co. is a family business.

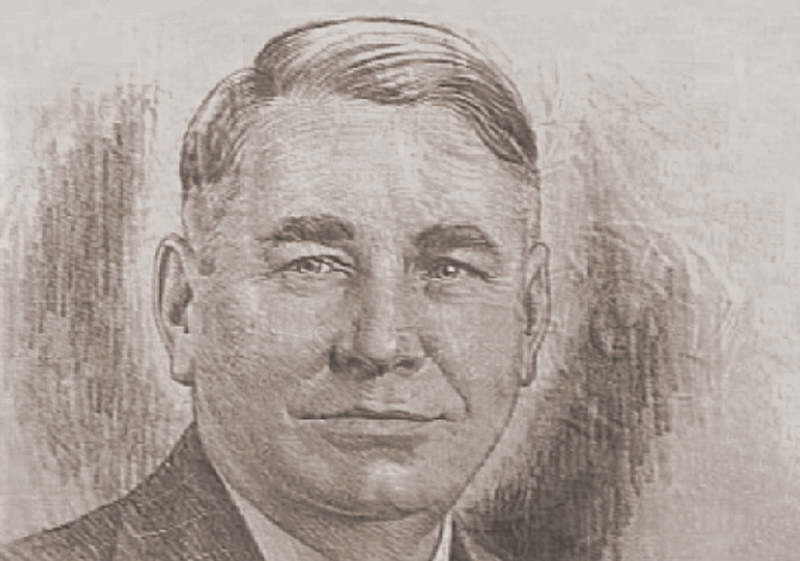

The company got its start in 1922, when Czech immigrant Anton J. Rose opened a small stamping shop in Cleveland. The company’s scope was broad at first, but eventually focused in on the automotive aftermarket, and then on serving original equipment manufacturers in that industry, said vice president of sales and marketing Terrence Sweeney. It was the company’s ability to create cost-saving designs for customers that led to its growth in that space, he said.

And Terrence Sweeney thinks it was employees’ design acumen that has allowed the company to persist for so long.

“We always flourished on that ideology,” he said.

A.J. Rose Manufacturing has seen a lot of change in its century of existence as technology and industry have evolved and grown. Ultimately, it comes down to the “mind work” of its employees, Terrence Sweeney said, and A.J. Rose Manufacturing is hoping its newest generation will be able to build upon the foundation it’s built over time.

That foundation goes back to the founder. Rose had three daughters and a son, Terrence Sweeney said, all of whom joined the company as the second generation.

Today, there are four families that hold equal ownership of the company, all cousins descended from founder Rose. They are the Rose, Pritchard, Warnkey and Sweeney families — and the fourth generation of the founder’s family has now gotten involved.

But when Terrence Sweeney talks about the next generation, he’s thinking beyond family. The company has low turnover, and it’s not uncommon for employees to stay for decades.

“People make the company,” he said. “Without good people, you don’t have a company.”

Today, A.J. Rose Manufacturing employs about 345. The company has two facilities in Northeast Ohio — its headquarters in Avon and its original manufacturing site in Cleveland — as well as one in India. The company declined to share financials. A.J. Rose Manufacturing primarily serves the automotive industry, with that market making up about 95% of its business, Terrence Sweeney said. The rest of the business is in industrial and HVAC. It primarily works with a variety of steels and aluminum.

The main focus in automotive for A.J. Rose Manufacturing is in the powertrain, everything from the transmission to the engine, Terrence Sweeney said.

A.J. Rose Manufacturing got its start making more general parts. Now it’s primarily a contract manufacturer for automakers, making parts specific to their products. What A.J. Rose Manufacturing makes today is “highly engineered, tight tolerance parts,” Terrence Sweeney said. And they help their customers save money and weight in their vehicles.

The company has taken pride in being able to consistently innovate and improve on customer designs, said sales engineer Torey Sweeney. That’s helped to build a strong reputation over time.

“We can take a $10 part and redesign it into a $5 part, and it’s lighter and performs better,” Terrence Sweeney said.

Working in automotive means the company is always thinking a few years ahead. The parts it makes today are going into vehicles a couple of product years in the future, Terrence Sweeney said.

And that’s more true today than ever, as the industry moves away from the internal combustion engine and toward electric vehicles. That’s a “major transformation,” Terrence Sweeney said.

“And as a result, that’s going to yield a lot of new design requirements,” he said. “It’s going to yield a lot of new engineering requirements. It’s going to yield a lot of new part numbers. It’s also going to eliminate a lot of part numbers as we go forward, too.”

A.J. Rose Manufacturing has always worked to look at where the industries it serves are going, Torey Sweeney said, so its employees can be working on solutions for problems yet to come.

A lot of companies that started around the same time as A.J. Rose Manufacturing grew to become large conglomerates or became absorbed into larger companies, Terrence Sweeney said. A.J. Rose Manufacturing opted to stay “small, nimble, flexible,” he said, and that’s helped it to adapt and survive over time.

A “strong vision” from the family behind A.J. Rose Manufacturing has been necessary to its longevity, said David Klotz, president of the Precision Metalforming Association in Independence. A.J. Rose

Manufacturing has been a member of the association for more than 50 years, and it’s been active locally and nationally in that time, Klotz said.

In addition to its vision, A. J. Rose Manufacturing has reinvested back into the company over the years, Klotz said, and upgrading technology and adding more automation is critical to ongoing success.